Understanding Drill Chucks

A drill chuck is a vital component of a power drill, serving as the mechanism that holds the drill bit securely in place. Without a reliable chuck, the entire drilling process can be compromised, leading to inefficiency, inaccurate holes, and potential damage to both the drill and the material being worked on. This article aims to delve into the various aspects of drill chucks, including their types, applications, and selection criteria, so you can make an informed decision. If you are in the market for a new drill chuck, understanding these factors will help you choose wisely.

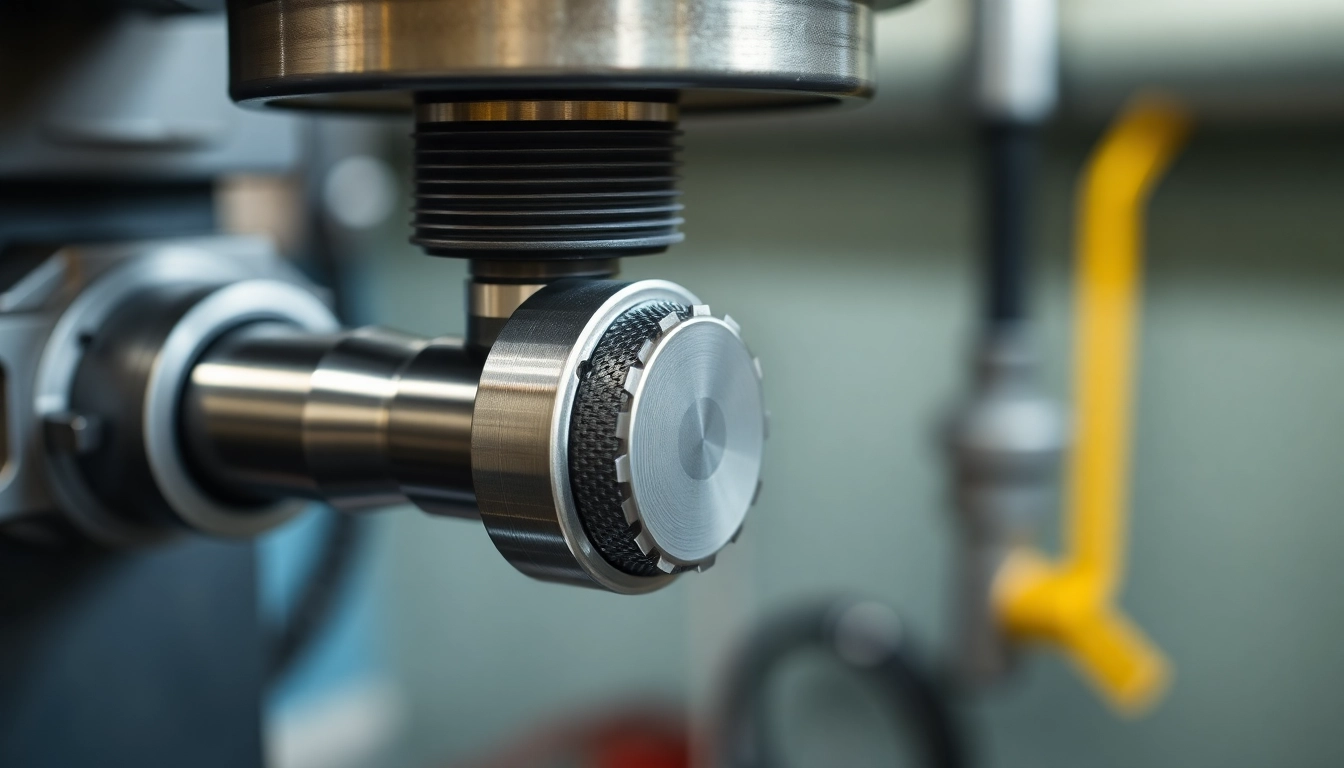

What is a Drill Chuck?

In its simplest form, a drill chuck is a clamp that secures a drill bit in a power drill. It can hold various sizes and types of drill bits, allowing for increased versatility in drilling applications. The chuck’s mechanism allows it to grip the shank of the bit tightly, ensuring it does not slip during use. Drill chucks are classified based on their design, operation, and maintenance requirements, making some more suitable for specific tasks than others.

Types of Drill Chucks Explained

Drill chucks come in several varieties, primarily classified as keyed, keyless, and hybrid types. Each serves different needs and preferences:

- Keyed Drill Chucks: These chucks use a physical key to tighten or loosen the grip on the drill bit. They provide a secure hold, which is particularly beneficial for heavy-duty applications. However, they require an additional tool (the key) to operate.

- Keyless Drill Chucks: As the name suggests, these chucks allow the user to tighten and loosen the grip by hand, eliminating the need for a key. They are more convenient for quick bit changes but may not offer the same level of grip as keyed chucks, especially for high torque applications.

- Hybrid Drill Chucks: Combining features of both keyed and keyless chucks, hybrids provide added versatility. They are designed to accommodate both manual tightening and key operation for heavy-duty applications.

How Drill Chucks Enhance Performance

The performance of a drill chuck can significantly influence the effectiveness of drilling tasks. Here’s how a high-quality chuck can enhance performance:

- Precision: A well-manufactured chuck ensures that the drill bit remains centered and securely fastened, which leads to more precise holes. This is particularly important in applications like woodworking and metalworking, where accuracy is paramount.

- Versatility: With various compatibility ranges, a suitable drill chuck allows users to switch between different bits seamlessly, optimizing the tool for various tasks.

- Durability: Quality chucks are built to withstand heavy usage, leading to longer tool life and reduced maintenance costs.

Drill Chuck Variations

Keyed vs. Keyless Drill Chucks

When it comes to selecting a drill chuck, understanding the differences between keyed and keyless options is essential. Keyed chucks, while slightly cumbersome due to the need for a key, provide heightened grip security—particularly for heavy-duty bit insertion. They are less likely to slip, making them a preferred choice for many professional woodworkers and metalworkers.

On the other hand, keyless chucks have gained immense popularity due to their speed and convenience. They allow users to quickly swap bits without fumbling with unnecessary tools. While generally sufficient for lighter applications, some users express concerns over grip strength, especially when used with larger bits in high torque situations. Therefore, consider your primary use cases when making a decision.

Size Matters: Popular Drill Chuck Sizes

Drill chucks are available in various sizes, often specified by the maximum diameter of the shank they can accommodate. Common sizes include:

- 10mm (3/8 inch): This size is prevalent for lighter drills and is ideal for smaller bits.

- 13mm (1/2 inch): A standard size in many consumer drills, suitable for a variety of tasks including woodworking and light metalworking.

- 16mm (5/8 inch) and above: These larger chucks are often found in more heavy-duty applications, such as industrial drilling equipment.

Choosing an appropriate size not only affects your drilling capabilities but also determines the types of bits you can use. Therefore, ensure that the chuck size aligns with your most commonly used bits for optimal results.

Adaptability: Drill Chuck Adapters and Extensions

Sometimes, the perfect chuck size or compatibility isn’t readily available. That’s where drill chuck adapters and extensions come into play. These accessories can modify existing chuck configurations to accommodate various bit sizes or styles, greatly extending the versatility of your power drill.

Adapters can convert a standard chuck to fit specialized bits, while extensions can help reach tight corners or greater depths. Using the right combination of adapters and extensions will open up new possibilities for your drilling projects, making your toolkit far more adaptable to diverse tasks.

Selecting the Right Drill Chuck

Assessing Your Drilling Needs

Before investing in a drill chuck, it’s important to assess your specific drilling needs. Consider the following factors:

- Type of Material: Different materials (wood, metal, plastic) may require specific types or sizes of drill bits, influencing your choice of chuck.

- Frequency of Use: If you’re a professional that uses drills daily, investing in a high-quality, durable chuck may save costs and downtime in the long run.

- Bit Size Compatibility: Evaluate the sizes of bits you currently own or plan to purchase. Ensure the chuck can accommodate these sizes effectively.

Evaluating Chuck Quality and Durability

Not all drill chucks are created equal. Some are built for heavy use and long-term reliability, while others are designed for occasional light tasks. Look for the following indicators of quality:

- Construction Material: Metal chucks tend to offer better durability than plastic alternatives. Look for chucks made from high-quality steel or other resilient materials.

- Locking Mechanism: A robust locking mechanism ensures that bits stay securely in place during use. Precision-engineered chucks with smooth opening and closing mechanisms are preferable.

- Brand Reputation: Established brands are generally a safer bet, as they often have a history of quality control and customer service. Research reviews and user feedback to gauge overall satisfaction.

Brand Considerations for Drill Chucks

Choosing a renowned brand can offer assurance regarding the quality and performance of a drill chuck. Brands like Jacobs, Rohm, and Albrecht are known for their precision and durability. Investigate their offerings, especially if you require specific features, such as high concentricity or adaptability to unique drill forms.

Moreover, consider seeking recommendations from professional contractors or craftsmen familiar with different brands. Insights from their experiences can guide your decision-making process substantially, ensuring you pick a chuck that aligns perfectly with your needs.

Installation and Maintenance Tips

How to Install a Drill Chuck Correctly

Proper installation of a drill chuck is paramount for optimal performance. Here’s how to do it correctly:

- Disconnect Power: Always disconnect the drill from the power source before attempting any change.

- Select the Right Chuck: Ensure the chuck you are installing is the correct size and type for your drill.

- Remove the Old Chuck: Use the appropriate tool to loosen and remove the existing chuck. Depending on the model, this may involve unthreading or using a chuck key.

- Install the New Chuck: Thread the new chuck onto the spindle, then tighten securely. Ensure it is centered and gripping tightly.

- Test Functionality: Insert a drill bit and check for security by spinning the chuck before plugging the drill back in.

Maintenance Practices for Longevity

Maintaining your drill chuck can prolong its lifespan and efficiency. Here’s a list of maintenance practices:

- Regular Cleaning: Remove any dust or debris from the chuck to prevent jamming and ensure a tight grip.

- Lubrication: Periodic lubrication may be necessary to keep the chuck’s moving parts functioning smoothly. Always refer to the manufacturer’s guidelines regarding suitable lubricants.

- Inspect for Wear: Regularly check for signs of wear or damage. If you notice any cracks or unusual wear patterns, it may be time to replace the chuck.

Troubleshooting Common Drill Chuck Issues

Even the highest quality drill chucks may encounter issues. Here are common problems and their solutions:

- Chuck Slippage: If bits are slipping during use, ensure that they are properly secured in the chuck. For keyed chucks, reinforce the gripping mechanism; for keyless chucks, make sure you are tightening adequately.

- Inability to Bit Change: If you can’t easily change bits, debris may be lodged in the chuck or the mechanism may be damaged. Cleaning or inspecting for damage should solve this problem.

- Excessive Vibration: This can indicate that the chuck is out of balance or that bits are not properly inserted. Inspect the chuck and bits to ensure they are correctly aligned.

Advanced Drill Chuck Techniques

Precision Drilling with High-Quality Chucks

For projects that demand utmost precision, investing in high-quality drill chucks pays dividends. These chucks often have advanced engineering that minimizes wobble and enhances concentricity, ensuring that the hole produced is as accurate as possible. Utilizing techniques such as slow-speed drilling and pilot hole creation can further improve accuracy, especially in challenging materials like metal or dense wood.

Consider practice drills on scrap material to ensure your technique is refined before committing to a final project.

Using Drill Chucks in Specialized Applications

Drill chucks can provide enhanced capabilities in specialized applications. For example, woodworking applications may require specialized bits and upgraded chucks to handle larger diameters or specific angles. Metalworking may present challenges regarding heat management, which requires proper bits and chucks designed to dissipate heat effectively.

Explore the possibilities of using your drill chuck in tandem with other tools and attachments to broaden its functionality, effectively turning a simple drill into a versatile power tool.

Innovative Uses for Drill Chucks in DIY Projects

Lastly, drills and their accompanying chucks can be leveraged in various DIY projects beyond standard drilling. Creative applications may include:

- Flame Polishing: By attaching rods to the chuck, they can serve as non-tool heating elements, offering versatility to projects requiring precise heating.

- Rotary Tools: Adapters can convert your drill into a rotary tool for tasks such as engraving or sanding.

- Creating Holes for Custom Fixtures: DIY enthusiasts can use advanced drill chucks to create custom holes for furniture, shelves, and more, resulting in unique designs tailored to their preferences.

Experimenting with these innovative uses can not only enhance your DIY capabilities but also extend the functionality of your existing power tools.