Introduction to Kemppi Welders

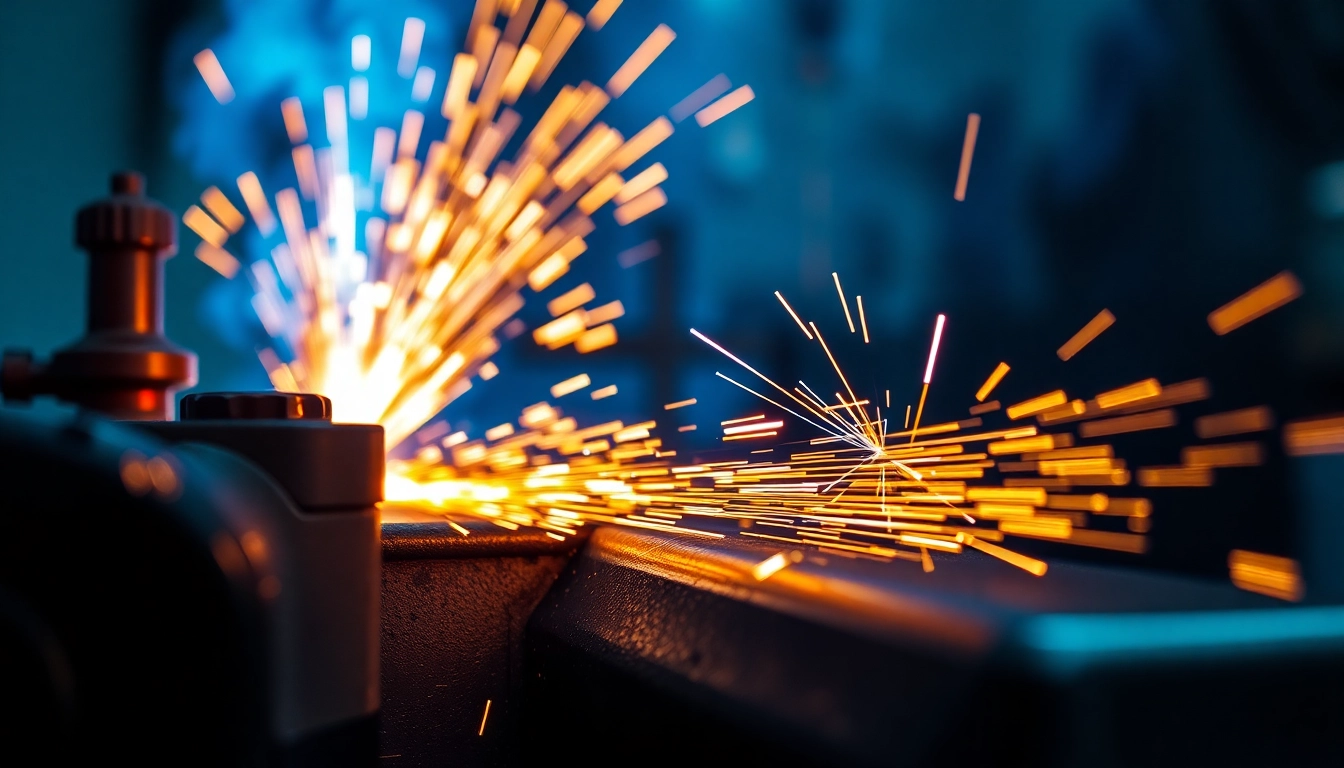

In the realm of welding technology, few names resonate as strongly as Kemppi. Renowned for their commitment to innovation and quality, kemppi welders stand out due to their advanced features and reliable performance. Founded in Finland, Kemppi Group Oy has been at the forefront of welding equipment manufacturing, providing solutions that meet the advanced requirements of various industries. This article will explore the essence of Kemppi welders, their types, advantages, and essential maintenance practices, designed to help you make informed decisions whether you’re a professional craftsman or a welding enthusiast.

Overview of Kemppi Brand

Kemppi is a globally recognized brand in the welding industry, celebrated for its small, precise, and efficient welding solutions. The company’s portfolio spans a diverse range of products, including MIG/MAG, TIG, and stick welders, as well as automated solutions. Notably, Kemppi welders are designed for a broad spectrum of applications, from industrial manufacturing to automotive repairs and hobbyist projects.

History and Innovation in Welding Technology

Founded in 1949, Kemppi has been an integral part of the welding industry’s evolution. Pioneering advancements such as the first electronic welding control system, Kemppi continues to push boundaries in terms of technology. Their focus on R&D has resulted in innovative products with features such as adaptive technology, which optimizes welding processes to ensure efficiency and quality.

Not only has Kemppi been instrumental in developing new welding processes, but they also embrace sustainability. With an increasing demand for eco-friendly technology, Kemppi invests in creating energy-efficient machines that minimize environmental impact, aligning with modern industrial needs and regulations.

Unique Features of Kemppi Welders

One key aspect that distinguishes Kemppi welders is their user-centric design, which emphasizes ease of use and advanced functionality. Their welders often feature:

- Adaptive Arc Control: This feature allows the welder to adjust parameters and optimize the arc to suit various welding conditions, enhancing both speed and quality.

- Robust Construction: Built to withstand tough environments, Kemppi welders are manufactured using high-quality materials that ensure longevity and reliability.

- Advanced Interface: Many models come equipped with intuitive interfaces that allow for simplified operation, making them accessible for beginners while offering depth for experienced welders.

Types of Kemppi Welders

The diversity of Kemppi’s welding solutions means there’s a welder suited for virtually every application. Understanding the different types of welders available can help you choose the right equipment for your specific needs.

MIG/MAG Welding Solutions

MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding are among the most popular welding processes used across various industries for their versatility and efficiency. Kemppi offers a range of MIG/MAG welders that excel in both manual and automated applications.

For instance, the Kemppi Master M Series is designed for high productivity. Equipped with advanced digital controls, these machines provide real-time data analysis, enabling operators to fine-tune settings for optimal welding results. The lightweight, portable design also makes these welders a favorite among contractors working on job sites.

TIG Welding for Precision

TIG (Tungsten Inert Gas) welding is known for producing high-quality welds, particularly in industries that require precision, such as aerospace and automotive. Kemppi’s TIG welders, like the MinarcTig series, are celebrated for their arc stability and control.

These welders come with features such as pulse control and precise heat management, essential for welding thin materials and achieving intricate designs. Their capability to adapt to different materials further enhances their versatility in specialized applications.

Stick Welding Applications

Stick (or SMAW) welding remains a tried-and-true method favored for its simplicity and effectiveness in various conditions, including outdoor environments. Kemppi’s stick welders are designed for high performance and reliability.

The Minarc 150 is a compact solution for both hobbyists and professionals, featuring intuitive controls and robust performance. Its lightweight design enables flexibility and ease of transport, making it ideal for maintenance and repair work.

Why Choose Kemppi Welders?

Choosing a welder is a significant investment, and Kemppi welders provide numerous advantages that justify their positions as preferred choices among professionals and enthusiasts alike.

Durability and Performance

Kemppi welders are renowned for their durability. Built to withstand the rigors of everyday use in various industrial contexts, they maintain high performance levels even in challenging environments. Users frequently note the longevity of these machines, which often leads to lower replacement costs and increased productivity over time.

Industry Standards and Certifications

All Kemppi welders comply with stringent international standards, ensuring they meet the quality and safety guidelines desired in today’s market. Certifications such as ISO 14001 and ISO 9001 underline the brand’s commitment to excellence in both product manufacturing and service delivery.

User Reviews and Satisfaction

Customer feedback verifies that Kemppi welders not only meet but often exceed expectations. Users appreciate their efficient operation, low maintenance needs, and outstanding technical support. Moreover, the user-friendly nature of controls and settings garners favorable reviews, making these welders suitable for operators of all skill levels.

Buying Guide for Kemppi Welders

Investing in a Kemppi welder requires careful consideration of various factors to ensure you choose the model best suited to your specific needs.

Budget Considerations

Prices for Kemppi welders vary widely depending on the model and features. It’s essential to establish a budget while also considering the long-term value that these machines provide. High-performance welders tend to cost more upfront but often result in savings down the line due to reduced downtime and lower maintenance costs.

Additionally, factor in the costs of consumables and potential accessories, which can vary between welding types. Understanding the full financial landscape can help you make a more informed choice.

Essential Accessories and Add-ons

To maximize the capabilities of your Kemppi welder, consider investing in additional accessories. Common add-ons include:

- Welding Torches: Ensure compatibility with your welder and choose a torch suited to your welding type.

- Protective Gear: Safety equipment such as helmets, gloves, and protective clothing are critical for safe operation.

- Electrodes and Filler Materials: Select high-quality materials that match the specifications of your chosen welding process.

Where to Purchase Kemppi Welders

Kemppi welders are available through various reputable distributors and retailers. It is advisable to seek authorized dealers that can provide reliable service, warranty, and support. Online platforms also offer options for purchasing, but ensure you verify the source’s credibility to avoid counterfeit products.

Maintenance and Care of Your Kemppi Welder

Proper maintenance is crucial for extending the life and performance of your Kemppi welder. Following best practices can prevent breakdowns and enhance efficiency.

Regular Maintenance Tips

Consistent care involves simple steps that every welder owner should undertake:

- Cleaning: Regularly clean the welder’s exterior and internal components to prevent dust and debris buildup.

- Inspections: Periodically check cables, hoses, and connectors for wear and tear. Promptly replace any damaged components.

- Calibration: Schedule routine calibration to ensure that the machine operates within specified parameters.

Common Repairs and Solutions

Whether due to normal wear or unintended mishaps, you may encounter issues that require attention. Some common repairs that users face include:

- Overheating Issues: Ensure the cooling system is functioning correctly and check for blockages in ventilation.

- Electrical Failures: Inspect for loose connections or damaged wiring; consult a professional if electrical repairs are needed.

- Inconsistent Arc Performance: Check for proper setup and calibration or any wear in the consumables.

Maximizing Welder Longevity

To extend the lifespan of your welder, adhere to the manufacturer’s guidelines for usage and maintenance. Avoid excessive strain on the machine, and store it appropriately in a climate-controlled environment to prevent corrosion and degradation of materials.

In conclusion, selecting the right Kemppi welder can significantly enhance your welding experience, whether you’re working on professional projects or pursuing a hobby. By understanding the different types of welders, their advantages, and the necessary maintenance requirements, you are well-equipped to make an informed decision that meets your welding needs.